Epichlorohydrin |

|

|

|

Item : un 2023 |

|

Details :Product Safety Assessment

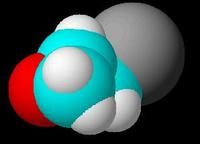

Epichlorohydrin Select a Topic: Names Product Overview Manufacture of Product Product Description Product Uses Exposure Potential Health Information Environmental Information Physical Hazard Information Regulatory Information Additional Information References Names • CAS No. 106-89-8 • Epichlorohydrin (ECH, EPI used as abbreviations) • (Chloromethyl)ethylene oxide • (D,L)-alpha-epichlorohydrin alpha-epichlorohydrin • 1,2-Epoxy-3-chloropropane • Chloro-2, 3-epoxypropane • 2,3-Epoxypropyl chloride • 2-(Chloromethyl)oxirane • chloro-1,2-epoxypropane • Chloropropene-1,2-oxide • Chloromethyloxirane • Chloropropylene oxide • Gamma-chloropropylene oxide • Glycerol epichlorohydrin • Epichlorohydrin glycerol • Glycidyl chloride • Oxirane, (Chloromethyl)- (9Cl) • Propane, 1-chloro-2,3- epoxy- (6Cl,8Cl) Product Overview • Epichlorohydrin (EPI) is an extremely versatile chemical intermediate used in a wide variety of applications. Approximately 76% of the world’s consumption of (EPI) is used to make epoxy resins.1 See Product Uses. • EPI is flammable. Direct, prolonged contact with pure EPI as liquid can severely damage the skin and eyes. Vapors may also produce eye irritation and damage to cornea of the eye. EPI is a probable carcinogen, a poison that can cause death at higher exposures, a mutagen and a skin sensitizer. 2 See Health Information and Physical Hazard Information. • Occupational exposures are possible; however, consumer exposures are not likely because end-use products are expected to contain only trace levels of EPI. Industrial operations use EPI in closed systems and are designed with engineering controls to minimize personnel and environmental exposures. 3 See Exposure Potential. • EPI is considered a hazardous chemical. If released into the environment, however, it biodegrades rapidly. 4 See Environmental Information. Manufacture of Product • Capacity – Dow is the largest producer of EPI in the world, with a capacity of 1 billion pounds/year (~453,000 metric tons/year) from plants in Freeport, Texas, and Städe, Germany.5 Annual global production is about 2 billion pounds/year (903,000 metric tons/year).6 • Process – The primary process for producing EPI consists of three steps: 1. Chlorination of propylene to form allyl chloride 2. Reaction of the allyl chloride with hypochlorous acid to produce glycerol dichlorohydrin 3. Reaction of the glycerol dichlorohydrin isomers with sodium hydroxide or calcium hydroxide to produce EPI. 7  Product Safety Assessment: Epichlorohydrin Page 2 of 4 Product Description EPI is a clear, colorless liquid with a sweet, pungent odor like chloroform. Product Uses8  EPI is an extremely versatile chemical intermediate used to produce a wide variety of other products, including: • Epoxy resins – to offer corrosion resistance, solvent and chemical resistance, hardness and adhesion. • Textiles – to improve wool’s resistance to moths, prepare fibers for dyeing, impart wrinkle resistance and prepare anti-static agents and textile sizings. • Papers, inks and dyes – to produce wet-strength paper sizing, special printing inks, textile print pastes, and ultimately paper and paperboard products that have improved printability, pigment retention, folding endurance and gloss. • Ion exchange resins – to produce anion exchangers used to clean polluted air and water. • Other applications that use EPI as a raw material include surface active agents used in cosmetics and shampoos; rubbers exhibiting resistance to extreme temperatures, fuel, oil and ozone for automotive and aircraft parts, seals and gaskets, and a myriad of other uses; and agricultural products such as insecticides, bactericides and fungicides. Exposure Potential Based on the manufacturing processes of and uses for EPI, the public could be exposed through: • Workplace exposure – Exposure can occur either in an EPI manufacturing facility or within the various industrial facilities that use EPI. Facilities using EPI are generally designed with leak-tight product handling systems (closed systems) and with good ventilation. All aspects of the handling operation, from delivery through reaction, should be carefully scrutinized for exposure potentials. Sampling activities should be thoroughly explored to prevent exposures.9 Personal protective equipment should be used routinely. The relatively high vapor pressure of EPI makes inhalation and exposures to the skin and eyes possible. Oral exposures and ingestion are possible, but much less likely due to the contained storage systems. Because of the flammability of EPI, all containers and handling equipment should be grounded. • Consumer exposure to products containing EPI – Consumer exposures are not likely because EPI is sold for industrial use to produce other products. End-use consumer products are expected to contain only trace levels of EPI. Consumer exposure would likely only come from environmental or large releases. • Environmental releases – Following proper transport and handling procedures minimizes the potential for spills to aquatic or soil environments that could result in exposure to wildlife or other organisms. Equipment should be properly designed, leak-tight and controlled to minimize exposures and releases. Improvements in production processes and incineration of vent gases have further decreased emissions.10 • Large release – Industrial spills or releases are infrequent and are generally well contained. If a large release of EPI does occur, non-emergency personnel should be cleared from the area. The area should be isolated and ignition sources removed because EPI is flammable. The public should be warned of the downwind explosion hazard. Procedures call for large spills to be captured, collected and reprocessed, or disposed of according to applicable governmental requirements. Emergency personnel should wear proper protective equipment and follow emergency procedures carefully.11 Fires involving EPI release toxic vapors. For more information, see the Safety Data Sheet. Product Safety Assessment: Epichlorohydrin Page 3 of 4 Health Information12 Contact with liquid and vaporous EPI should be avoided. EPI may be fatal if inhaled at high enough concentrations. Lung injury, which may be delayed, can result from inhalation of EPI vapor. Liver and kidney injury can result from respiratory exposure or prolonged skin contact. Although it is unlikely that acutely toxic amounts of EPI would be ingested in the course of ordinary operations, serious injury or death could result. EPI is irritating and damaging to the skin and eyes. Prolonged contact will cause serious chemical burns to the skin. EPI has also caused allergic skin reactions and so is considered a skin sensitizer. Eye contact with EPI liquid will produce moderate irritation with corneal injury, and exposure to EPI vapors will irritate the eyes and can produce corneal injury. EPI has a sweet, pungent smell with an odor threshold ranging from 1-25 part per million (ppm). Although this odor threshold is lower than the 100 ppm level that causes marked nose and eye irritation, workers must not rely on odor, or on eye and nose irritability, as a warning or indicator of exposure potentials.13 EPI causes cancer in laboratory animals and is considered a probable human carcinogen by the International Agency for Research on Cancer (IARC). EPI is considered genotoxic because it has been shown to cause cell mutations and to damage chromosomes. For more information about the health hazards of EPI and recommended protective equipment, view the Safety Data Sheet. Environmental Information EPI is a mobile, volatile liquid that biodegrades primarily through hydrolysis. Contamination of soil and water should be minimized by spill containment and removal whenever possible. When spilled, EPI may exert a toxic action before hydrolysis, but its bioconcentration potential is low because of its relatively high biodegradability.14 Physical Hazard Information15 EPI is a liquid at room temperature with a melting point of -57°C (-70ºF) and boiling point of 116.4°C (241.5ºF). The vapor pressure of EPI is 17 mm Hg (25ºC), while the water solubility is 6.6 percent at 20°C (68ºF). EPI is flammable and toxic fumes are released in fire situations. If there is an industrial event, vapors may travel a long distance. Ignition and/or flash back may occur. Ground and bond all containers and handling equipment. Keep vapors out of sewers to avoid fire or explosion.16 Additional physical property information for EPI is available on the Epoxy Products and Intermediates web site, or see the Safety Data Sheet. Regulatory Information Regulations may exist that govern the manufacture, sale, transportation, use and/or disposal of Epichlorohydrin. These regulations may vary by city, state, country or geographic region. Information may be found by consulting the relevant Safety Data Sheet or Contact Us. Additional Information • Safety Data Sheet • DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage (544KB PDF) • Chemical Economics Handbook Report Epichlorohydrin For additional business information about EPI, visit Dow’s Epoxy Products and Intermediates web site. References 1 Chemical Economics Handbook Report Epichlorohydrin, SRI Consulting, September 2004, abstract. 2 DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage, Dow Form No. 296-01301-1299X WC+M, pages 16-17. Product Safety Assessment: Epichlorohydrin Created: 4/20/2006 The Dow Chemical Company Page 4 of 4 3 DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage, Dow Form No. 296-01301-1299X WC+M, page 20. 4 DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage, Dow Form No. 296-01301-1299X WC+M, page 27. 5 DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage, Dow Form No. 296-01301-1299X WC+M, page 2. 6 Chemical Economics Handbook Report Epichlorohydrin, SRI Consulting, September 2004, abstract. 7 Synthetic Strategies to Drug Molecules, (www.uea.ac.uk/~c058/StrategiesforDrugSynthesis1.pdf), page 5. 8 DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage, Dow Form No. 296-01301-1299X WC+M, pages 14-15. 9 DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage, Dow Form No. 296-01301-1299X WC+M, page 20. 10 DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage, Dow Form No. 296-01301-1299X WC+M, pages 20 and 27. 11 Safety Data Sheet, page 5. 12 DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage, Dow Form No. 296-01301-1299X WC+M, pages 16-17. 13 DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage, Dow Form No. 296-01301-1299X WC+M, pages 16. 14 DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage, Dow Form No. 296-01301-1299X WC+M, page 27. 15 DOW Epichlorohydrin Product Stewardship Manual: Safe Handling & Storage, Dow Form No. 296-01301-1299X WC+M, pages 10-11. 16 Safety Data Sheet, pages 3-5. NOTICE: Although the information and recommendations in this document or at a related Internet Web site (hereinafter "Information") are presented in good faith and believed to be correct, The Dow Chemical Company and its consolidated subsidiaries (Dow) make no representations or warranties as to the completeness or accuracy of Information. Information is supplied upon the condition that the persons receiving same will make their own determination as to its suitability for their purposes prior to use. In no event will Dow be responsible for damages of any nature whatsoever resulting from the use of or reliance upon Information or the product to which Information refers. Nothing contained herein is to be construed as a recommendation to use any product, process, equipment or formulation in conflict with any patent, and Dow makes no representation or warranty, express or implied, that the use thereof will not infringe any patent. NO REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED, OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OF ANY OTHER NATURE ARE MADE HEREUNDER WITH RESPECT TO INFORMATION OR THE PRODUCT TO WHICH INFORMATION REFERS. Dow makes no commitment to update or correct any information that appears on the Internet or on its World-Wide Web server. The information contained in this document is supplemental to the Internet Disclaimer and is not intended to be all-inclusive as it relates to use, handling, storage, disposal and all other described activities. Recipients must make their own determination of suitability and are responsible for compliance with all applicable governmental requirements. This information is offered solely for your consideration and verification and in no event will Dow be responsible for damages of any nature whatsoever resulting from the use or reliance upon this information or the product to which this information pertains. |

|

| [Next] [Previous67-63-0] | |

|